Thermal Imaging Services

We conduct thermographic inspections across a variety of sites and provide detailed reports with accurate analysis

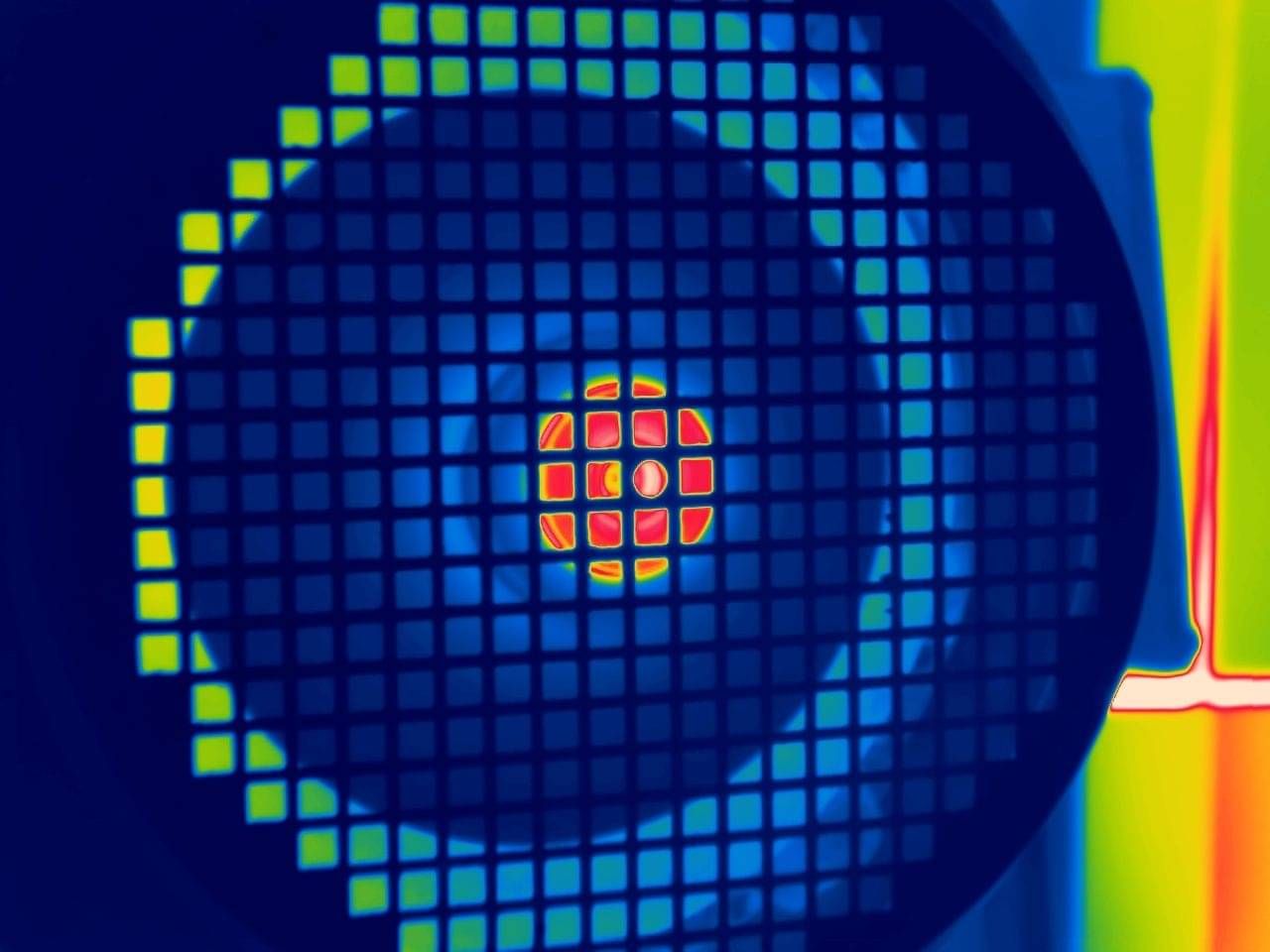

Electrical Thermal Imaging

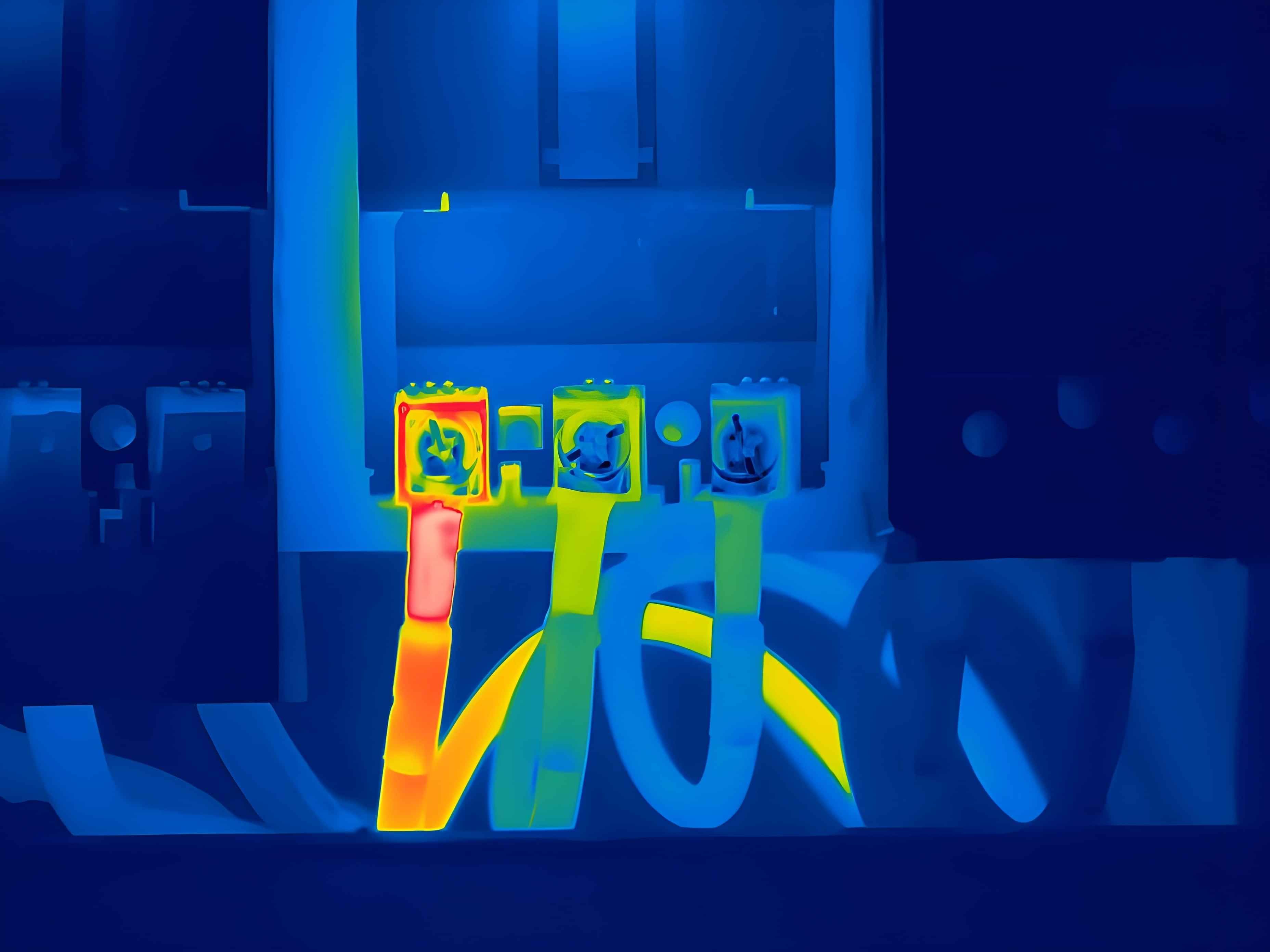

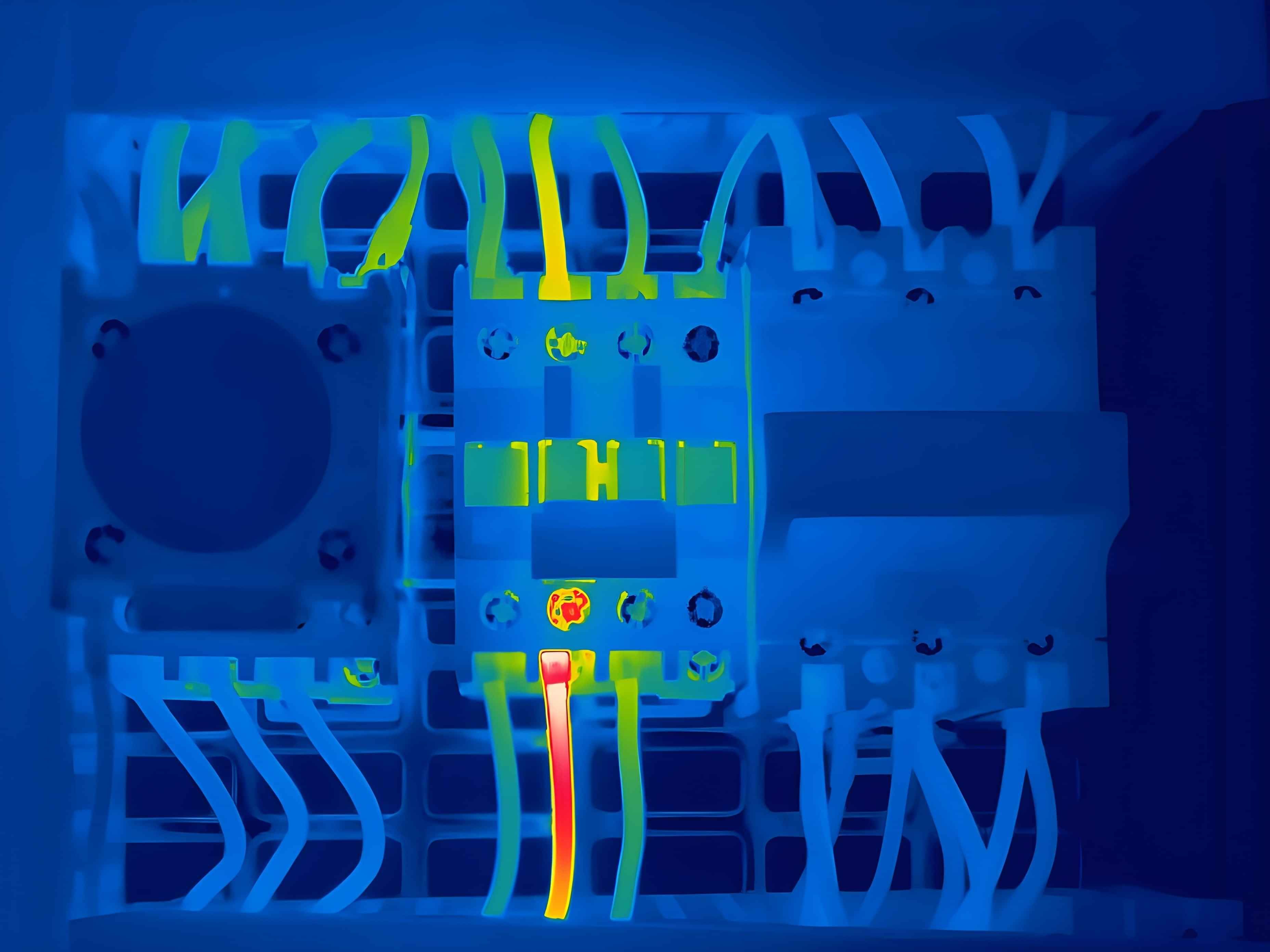

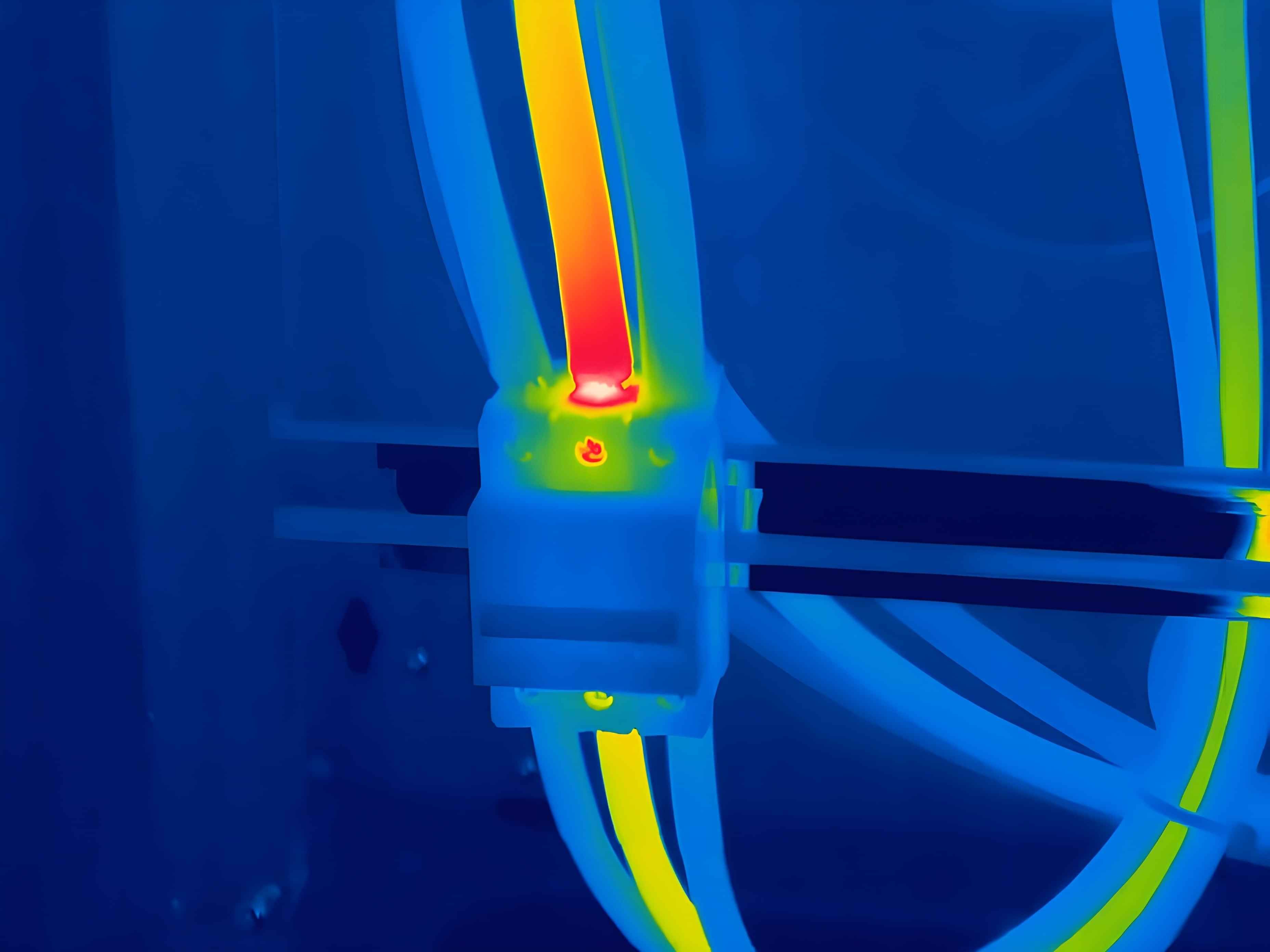

Each year, over 1,500 fires in New Zealand are caused by electrical equipment. Our electrical thermal imaging inspections can detect excessive heat build-up and other early warning signs, enabling our clients to perform targeted corrective action before issues escalate. Early detection of faults not only enhances safety but also minimizes downtime, fires, failures, and expensive repairs.

Electrical items we inspect include:

Switchboards, control cabinets, wiring, metering, distribution systems, PFC units

UPS battery back up systems, PV solar arrays, DC systems, generators

Motors, drives, starters, power supplies, harmonic filters

Lighting, sockets, switches, underfloor heating, appliances, chargers

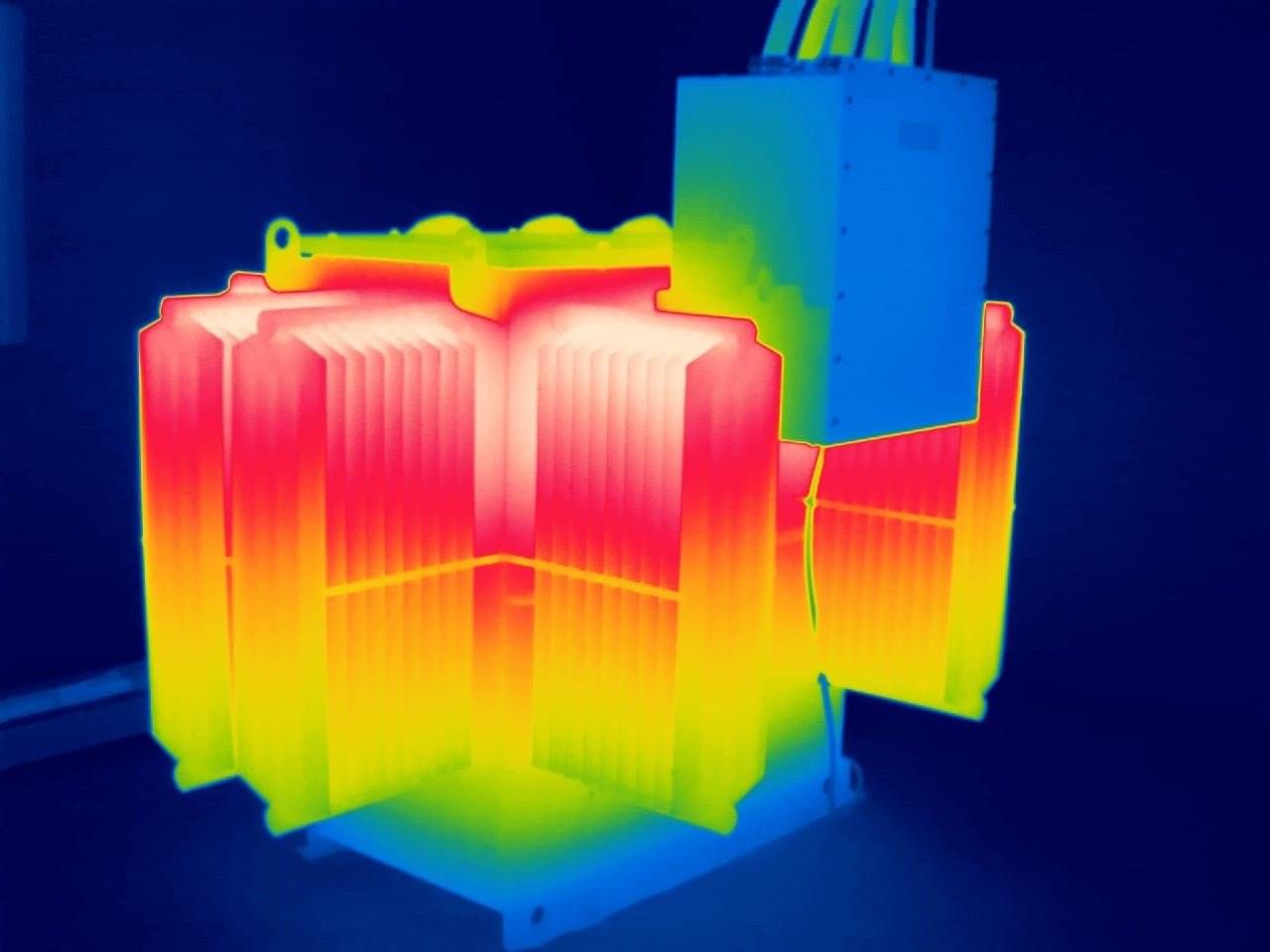

High voltage transformers, transmission lines, switchgear, ripple systems

Common issues we detect include:

Loose connections, poor terminations, corroded contact surfaces, insulation failures

Overheating components such as circuit breakers, fuses, isolators, contactors etc

Faulty cables, joints, and switchgear

Load imbalances in multi phase systems, high resistance components

Excessive heat in cable looms, trunking, and cable management systems

Mechanical Thermal Imaging

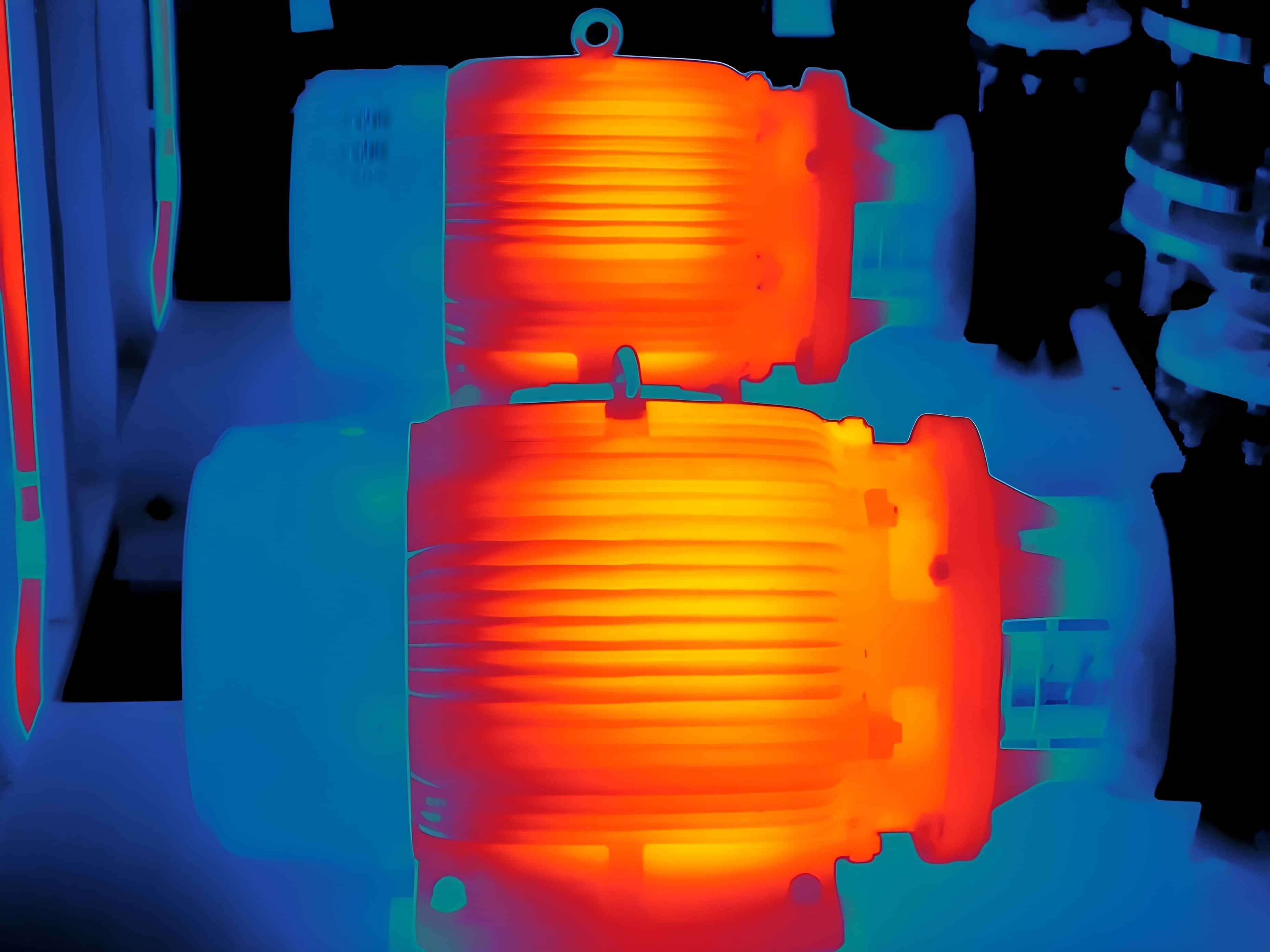

Mechanical equipment is essential across various industries. Businesses rely on machinery to create their products, automate processes, reduce labour costs, and maintain high output levels. As part of your preventative maintenance or condition monitoring plan, investing in regular thermal imaging inspections can extend the reliability and life span of machinery, minimize downtime, and prevent costly repairs or replacements.

Mechanical items we inspect include:

All types of production, manufacturing, and process machinery

Conveyors, motors, drive systems, elevators, pumps, palletisers, formers, mixers, fillers, crushers, ovens, hydraulic systems, winches, cranes, robots etc

HVAC units, extraction systems, heat exchangers, compressed air systems, boilers

Common issues we detect include:

Excessive friction due to worn bearings, poor lubrication, components touching etc

Misaligned components - shafts, drive belts, gear sets, motors, rollers etc

Fluid blockages, fluid and gas leaks, poor ventilation

Material degradation, delamination, corrosion, contamination

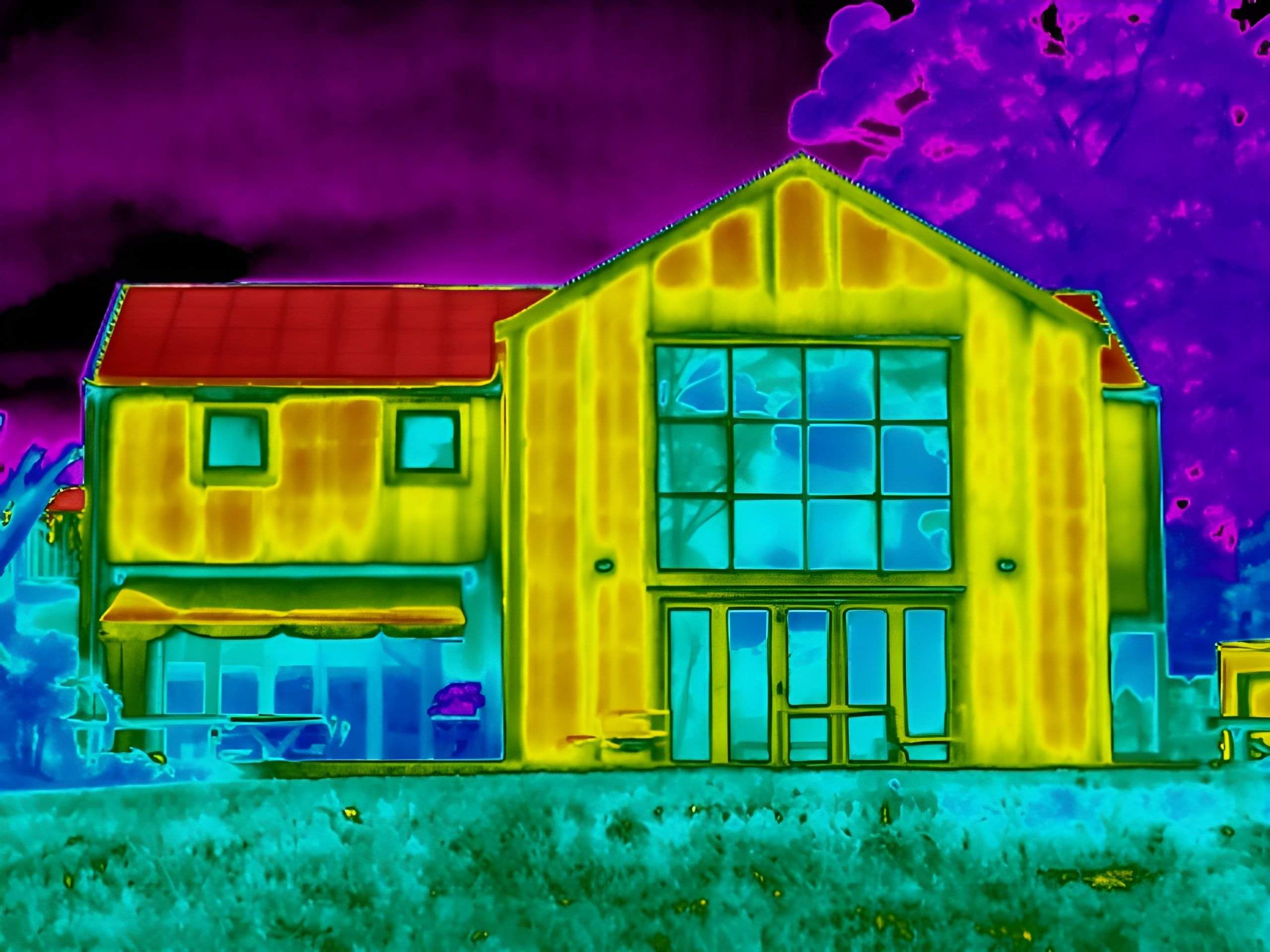

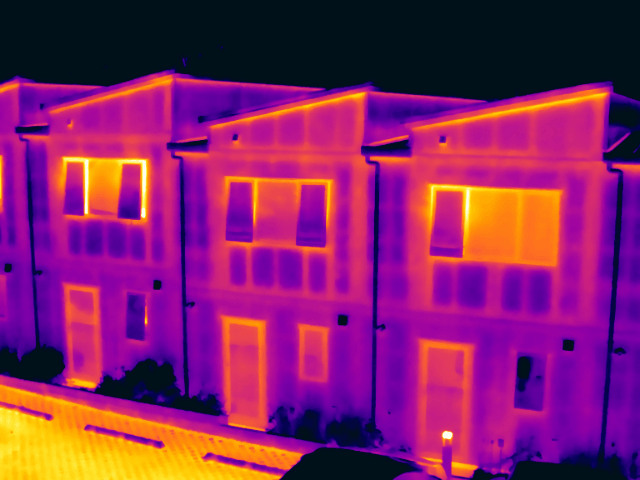

Building Thermal Imaging

Buildings can develop various issues due to poor construction, installation defects, material degradation, subsidence, extreme weather, and environmental factors. Our thermal imaging inspections can be used in most building types to identify hidden issues and concentrate repairs where they are needed most.

Common issues we detect include:

Water ingress and leaks, trapped moisture, condensation, air leaks

Poor heating/cooling energy efficiency, missing or defective insulation

Cracks and voids in structural components

Delamination of composite materials, roofing, facades

Electrical Periodic Verifications

Many insurance companies require businesses to carry out an electrical periodic verification to Sections 3, 4, or 5 of AS/NZS 3019:2007. This is a comprehensive inspection involving a detailed visual examination of your entire electrical system, as well as limited or full testing such as earth continuity, equipotential bonding, polarity, earth fault loop impedance, insulation resistance, and RCD testing. We can conduct a periodic verification and prepare a detailed report with recommendations and a certificate of verification to meet your insurance requirements.

We can thermal image anything - our common clients include:

Commercial - offices, warehouses, datacentres, shopping centres, retail shops, schools, hospitals, pools, theatres

Hospitality & accommodation - hotels, restaurants, bars, apartment blocks, retirement villages, multi-use sites

Production, manufacturing, processing - food/beverage, packaging, fabrication, machining, printing, lumber, chemicals

Marine - ports, marinas, dry stacks, boat yards, vessels, shore power supplies

Utilities - water and waste assets, oil and gas sites, council/government assets, recycling and rubbish, public facilities

Electricity networks - high voltage generation, transmission, distribution, transformers

Who usually engages our services?

Building and company owners

Maintenance, facility, building, project, and property managers

Other trade services such as electrical, plumbing, building, and leak detection companies

Insurance and compliance companies

Engineers and architects